Deciding on the production method for a new item can be a bewildering experience. For most brandedapparel manufacturers, it means choosing between “full-package”, “cut-make-trim” or some other approach while balancing a complex set of quality, consistency, brand reputation, customer service and cost variables.

a bewildering experience. For most brandedapparel manufacturers, it means choosing between “full-package”, “cut-make-trim” or some other approach while balancing a complex set of quality, consistency, brand reputation, customer service and cost variables.

Over hundreds of projects and scores of clients, Distinctive Designs 21 has seen choices that led to great and not-so-great outcomes. This whitepaper has a simple objective: pass on what we’ve learned so others can make the best decision for their unique situation.

How we got here

Let’s back up. As our industry was coming of age nearly a century ago in the streets and avenues of New York City, it was common to make patterns in one place, cut in another and sew in still another. This required that manufacturers frequently move merchandise but it generally worked out since these contractors were relatively close to each other.

As the industry matured, some vendors coalesced into an all-in-one “cut, make and trim” or CMT shop. Branded manufacturers developed their supply networks while maintaining the core value-added functions of design, patterning, development, fabric and trim supply, shipping and finance.

Methods changed again as production moved off shore in the 70s, 80s and 90s. Manufacturers discovered that the great distances led to nearly insurmountable coordination challenges. As they evolved to place more and more functions into the hands of foreign partners, full-package programs or FPP emerged and even became dominant.

While FPP can mean different things depending upon where you operate, it generally specifies that the manufacturer develops styles and specifications (i.e. tech packs, fabric designations etc.) and asks their contractor factory to develop patterns, source materials, make samples, produce and ship finished goods. In addition to equipment, efficient and well-functioning full-package program suppliers must have: a pool of skilled employees, management expertise, up-to-date technology and robust financial resources.

Lessons learned from front lines

The idea of off-loading operational responsibility to a partner and concentrating efforts on styling and the increasingly stern demands of retailers had great appeal and led many manufacturers to embrace “full package”.

Some of these marriages had happy endings; others ran into trouble after a brief honeymoon period. Drawing on everything we’ve observed, here are a few things you might want to bear in mind as you approach decisions about production contracting.

-

You can’t delegate schedules

Apparel production has a lot of moving parts and any one of them can throw a wrench into always tight timetables. Keeping these complex operations on pace to deliver to retailers is a monumental task and manufactures intuitively like the idea of having a single point of accountability when it comes to hitting delivery dates.

But having someone to blame makes no difference to your retailers—who won’t be getting their goods. After watching frustrated manufacturers levy and try collecting on chargebacks to factories, it seems to us to be poor path to go down. The truth is that we are at the point where most small- and medium-size manufacturers can’t do without contrators. Unless things get really bad, fining or firing them is rarely an option.

-

Purchasing power can be a case of inflated expectations

Many full-package clients have told us that they utilize their contractors to tag onto their partner’s purchasing coattails. They’ve convinced themselves that their cost structure would suffer if they needed to make these buys on their own.

This is a compelling argument for smaller manufacturers utilizing commodity-type fabrics. But manufacturers should go into the relationship with open eyes, knowing that their ability to differentiate their fabrics will be limited to what their contractor buys on a regular basis.

-

Relinquishing brand control can win the battle; lose the war

Manufacturers typically task their full-package partners to source; based on their specifications, elements like labels, patches, hang tags, packaging and other components that carry the manufacturer’s branding message to retailers and consumers. Far too often these, important features are technically correct but off the mark in terms of polishing a brand image. Disappoints are magnified when multiple contractors are involved and factory-to-factory inconsistencies become a real sore spot for the brand.

-

Full package can make it harder to meet retailer demands

Retailers are all seeking greater agility in their supply chains. To accomplish this, they are continually shortening turnaround times on orders so they can be more reactive to consumer demand and reduce their investment in merchandise inventory.

As full-package contracting vendors become larger and acquire more leverage, they are demanding that smaller customers give them more, not less, time to prepare and ship their orders. All this places some manufacturers in the uncomfortable position of having two masters.

-

Compliance is still on your shoulders

Bad publicity regarding labor exploitation or poor environmental practices has struck and damaged many firms. In response to these issues, manufacturers have developed written codes designed to guard against this type of vulnerability.

A half a world away, it is nearly impossible to peer into the operations of full-package partners and understand where they are (or are not) employing sub-contractors to do piece work or other production operations. For manufacturers who have found themselves in hot water over sustainability, environmental stewardship, worker safety and labor standards, it has commonly been subs not the FPP partner who was the violator. Cries of: “I didn’t know” do not go down well in today’s hyper-sensitive environment.

-

Make sure cost savings are real

Some manufacturers who’ve gone down the full-package path have been unpleasantly surprised that the price is not what it appeared to be. When quoting a finished garment price, it is common for full-package vendors to provide pricing in country of origin, leaving manufacturers with the responsibility for freight, duties, penalties, customs fees and other costly add-ons.

We advise going to the trouble of computing the true landed cost to retailers. When doing so, some clients have seen their “savings” greatly diminished. Indeed, after investigating we’ve often found that clients could have achieved a lower overall cost by maintaining control of key trim and packaging components.

-

Good FPP marriages take work

Many of our clients go into a full-package program with the expectation that the relationship is going to streamline their operations, reduce the activities associated with producing and delivering apparel. To some degree this is true; but the “morning-after” realization is that it takes more time than they imagined approving samples and finished production. If you have three contract locations that means receiving and inspecting three set of samples and three sets of finished goods—a time consuming exercise, particularly when problems are found.

A hybrid approach: The “Brand Control Program”

Some of our clients have, no doubt, benefited from FPP programs. We’d say that those in the best position to do so are manufacturers offering commodity goods or those with highly engineered specifications that can be clearly detailed and quantified in tech packs.

This contracting method may also work out well for smaller brands that are able to accomplish all of their production in a single location, reducing the variability that is introduced by multiple sourcing locations.

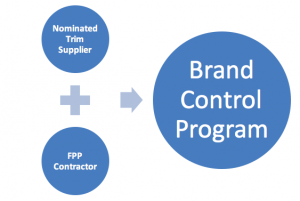

For manufacturers that are quality oriented and attempting to build a sustainable brand in our industry, we suggest a revised approach, something we call a Brand Control Program.

We think of this as a version of full-package within which the manufacturer maintains control of key branding elements via a separate contract with a nominated trim supplier. It essentially sets up a bi-lateral relationship between the FPP vendor and the trim supplier to work together on behalf of the manufacturer.

The manufacturer in a brand control program benefits from having centralized production of its key branding elements like patches, labels, packaging, hang tags, price strips etc. so that they are exactly same in all locations. This approach asks the trim supplier to hold these elements in inventory and deliver them as needed to the contracting factory. When employed, this practice has the benefit of leveraging the trim supplier’s balance sheet and shortening production lead times.

As we said at the outset, production method choices can be agonizing decisions and ones with many unintended consequences. We hope this discussion has been useful in its illumination of the things that can happen (and not happen) with full-package programs.

If a brand control program sounds like a good fit for your business, the client service team at Distinctive Designs 21 would be pleased to talk with you in detail about this approach.

About Distinctive Designs 21

We are a full-blown trim management firm collaborating with product teams at leading

apparel brands worldwide to protect quality, eliminate unnecessary costs and keep production on track. Our team of battle-tested developers, production coordinators, inventory managers and international logistics experts take trim sourcing, development and management off your plate so you can maintain focus on customer accounts.

No Comments